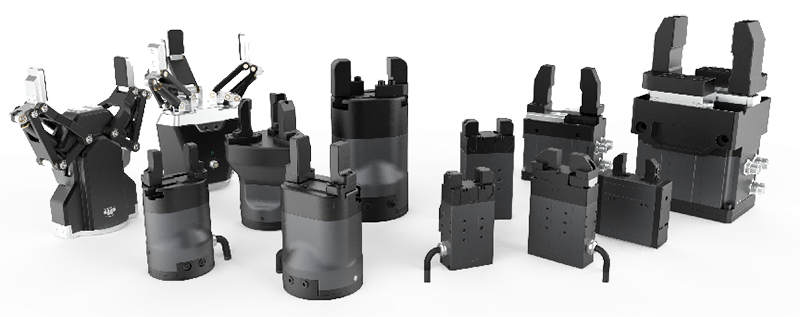

Cov khoom siv hluav taws xob gripper series yog cov khoom lag luam nrog qib siab ntawm qhov tseeb.Kab lus no yuav qhia txog lub hauv paus ntsiab lus ntawm cov khoom siv, cov yam ntxwv ntawm cov khoom, thiab cov kev siv tshwj xeeb ntawm cov khoom siv hluav taws xob.Kuv vam tias cov neeg nyeem tuaj yeem pib tsim kev paub txog cov khoom siv hluav taws xob gripper.yooj yim impressions thiab kev nkag siab.

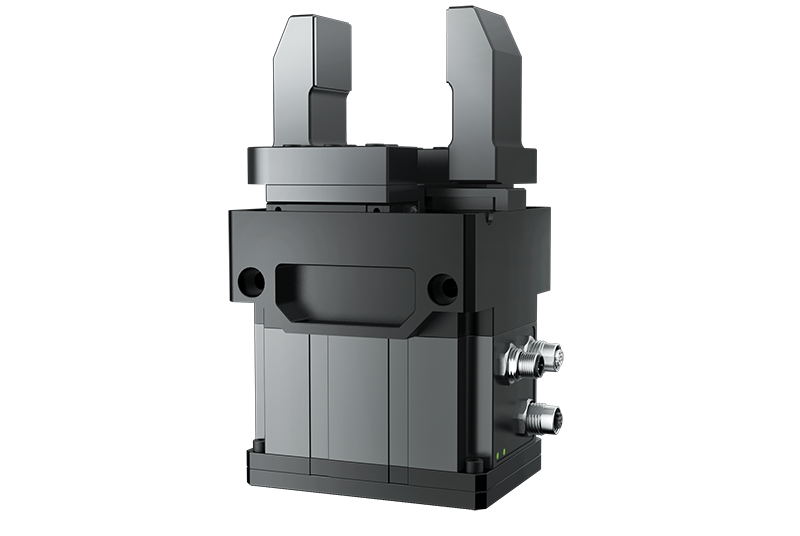

1. Mechanical txoj cai ntawm hluav taws xob gripper

Txhawm rau muab nws yooj yim, lub hauv paus ntsiab lus ntawm cov hluav taws xob gripper yog qhov ua haujlwm ntawm ob lub pistons.Txhua lub piston txuas nrog cov ntiv tes pneumatic los ntawm cov menyuam thiab tus pin hyperbolic, yog li tsim ib qho tshwj xeeb tsav.Nyob rau hauv txoj kev no, cov ntiv tes pneumatic tuaj yeem txav axially mus rau qhov chaw, tab sis txhua tus ntiv tes tsis tuaj yeem txav ntawm nws tus kheej.Yog tias tus ntiv tes pneumatic txav mus rau qhov sib txawv, lub piston yav dhau los compressed yuav raug tso tawm thiab lwm lub piston yuav raug compressed.

Lub puab tsaig sib npaug ntawm cov hluav taws xob gripper yog tsav los ntawm ib lub piston, uas nws lub crank yog tsav los ntawm tus ncej nws tus kheej.Ob lub puab tsaig txhua tus muaj qhov tsis sib haum xeeb crank.Txhawm rau kom txo qis kev sib txhuam, lub claw thiab lub cev kuj tau txais cov qauv kev sib txuas ntawm steel pob swb.

2. Khoom nta ntawm hluav taws xob gripper

1) Lub cev ntawm cov hluav taws xob gripper muaj lub cev muaj zog, uas yog cov khoom lag luam ntse sib xyaw ua ke tsav thiab kev sib txuas lus.Ntxiv mus, tag nrho cov ntim ntawm cov hluav taws xob gripper yog me me, uas kuj yooj yim dua rau cov neeg siv rau nruab thiab siv.

2) Lub tshuab hluav taws xob muaj lub zog sib hloov ua haujlwm thiab clamping muaj nuj nqi, thiab lub puab tsaig rotating ob lub puab tsaig tuaj yeem paub txog kev sib hloov thiab kev ua haujlwm clamping tib lub sijhawm.

3) Cov hluav taws xob gripper muaj peev xwm ntawm high-precision positioning thiab voltage tiv thaiv.Nws yog manifested nyob rau hauv hais tias lub hwj chim gripper tsis tau tsuas yog nrhiav tau lub real-time txoj hauj lwm ntawm kev sib hloov thiab clamping nrog high precision, tab sis kuj muaj ntau yam kev tiv thaiv functions xws li overvoltage, overcurrent, stalled rotor thiab overheating rau cov khoom voltage thaum lub sij hawm ua hauj lwm txheej txheem.

4) Qhov ceev thiab tam sim no ntawm cov hluav taws xob gripper tuaj yeem hloov kho txhua lub sijhawm thaum lub sijhawm ua haujlwm, thiab kev hloov kho yuav siv sijhawm.Nruab nrog dual NPN opto-kev sib cais inputs los tswj lub pem hauv ntej thiab rov qab tig ntawm lub cev muaj zog.

3. Qhov zoo ntawm hluav taws xob gripper

1) Lub zog hluav taws xob tuaj yeem ua tiav qhov kev tswj xyuas qhov tseeb.Yog li ntawd, hluav taws xob grippers yog qhov tsim nyog rau qee qhov xwm txheej uas yuav tsum tau ua nruj me ntsis rau kev tswj lub zog, xws li thaum siv hluav taws xob grippers los tuav nyias thiab tsis yooj yim, nws yuav tsis ua rau cov khoom puas tsuaj.

2) Cov hluav taws xob gripper tuaj yeem hloov kho qhov nrawm nrawm, kom paub txog cov txheej txheem tuav ntawm cov khoom sib txawv.

3) Lub clamping ceev ntawm hluav taws xob gripper kuj tuaj yeem tswj tau yooj yim.Hauv cov txheej txheem, kev npaj tswv yim thiab kev tswj hwm kev tswj hwm tuaj yeem siv los ua kom raug thiab nrawm ua tiav cov haujlwm ua haujlwm uas xav tau los ntawm kev tsim cov kev pab cuam thiab txhim kho kev ua haujlwm ntawm cov gripper.

4) Kev sib xyaw tsav thiab tswj kev tsim hluav taws xob gripper ua kom yooj yim rau kev xaim ntawm cov kab ntau lawm, txuag ntau qhov chaw thiab ua kom muaj kev nyab xeeb thiab huv ntawm ib puag ncig.

4. Kev siv tswv yim ntawm hluav taws xob gripper

1) Workpiece ID nkag mus

Qhov chaw uas cov hluav taws xob gripper yog siv rau kev txheeb xyuas qhov chaw ua haujlwm feem ntau yog siv hom clamping los ntxig rau lub workpiece rau kev txiav txim siab ntev.Nws yog tsuas yog los tiv thaiv kev sib tov ntawm workpieces nrog txawv diameters los yog outflow ntawm substandard khoom.

2) Workpiece nias-hauv

Kev sib xyaw ua ke ntawm cov hluav taws xob gripper ua ke nrog cov pas nrig thawb rau hauv qhov chaw ua haujlwm tuaj yeem siv qhov kev txiav txim siab los kuaj xyuas qhov yuam kev ntawm "txawm tias cov khoom puas raug nias" lossis "txawm tias lub workpiece raug chucked".Cov xwm txheej muaj xws li lub davhlau ya nyob twg xovxwm-fitting ntawm me me, riveting ntawm vaj tse, thiab lwm yam.

3) Clamping ntawm cov khoom tawg yooj yim

Lub clamping quab yuam, ceev, thiab stroke ntawm hluav taws xob gripper tuaj yeem hloov kho tau yooj yim, yog li nws tuaj yeem siv rau clamping ntawm cov khoom tsis zoo xws li cov raj, cov qe, thiab cov qe yob.

4) Sab hauv txoj kab uas hla

Lub clamping hom ntawm cov hluav taws xob gripper tuaj yeem siv los txiav txim siab ntev ntawm lub puab txoj kab uas hla ntawm lub workpiece.

Post lub sij hawm: Dec-12-2022